Henry Kemp Ltd supplies and installs every type of roadstud approved for use on UK roads.

All roadstuds used in the UK must have been road trialled and approved to EN1463 which is the standard applied across Europe.

All roadstuds used in the UK must have been road trialled and approved to EN1463 which is the standard applied across Europe.

Inset depressible roadstuds consist of a flexible rubber insert with reflectors, housed inside a cast iron base. They are installed by milling a cavity into the road surface and fixing them into position with hot poured bitumen. The “depressible” part of the description means that the reflector elements housed in the rubber insert allows them to be self-cleaned by rain and the passage of traffic which causes the reflectors to pass across a wiper.

Catseyes are the world's first roadstud, created by Halifax inventor Percy Shaw who took his patent out in 1934. Since then, they have undergone several design changes to meet increasing traffic demands and keep abreast of performance requirements.

Lightdomes are similar in many respects to Catseyes and are installed by the same method. They offer a slightly different alternative to the Catseye.

Inset non-depressible roadstuds are milled into the road surface and fixed into place using molten bitumen. The reflectors are in a fixed position and rely on a combination of rain and contact with vehicle tyre treads for self-

cleaning.

Armourstuds are a reflectorised one-piece glass construction which require a much smaller cavity to be milled into the road surface than the other inset roadstud types. The reflector principle employed in Armourstuds is catadioptric and uses internal refraction and reflection.

The C80/381 type roadstud consists of a fixed plastic reflector unit housed in a cast iron base. The reflectors are corner cube air gap type.

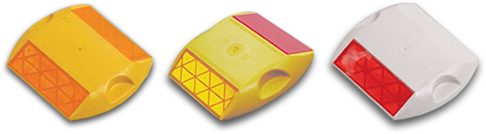

Surface mounted roadstuds do not require a cavity to be milled into the road surface, therefore the installation cycle is shorter than with inset studs and milling/drilling equipment is not required. This type of stud is typically made of plastic and is fixed directly to the surface using hot melt bituminous material.

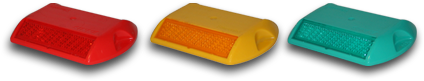

Solar powered roadstuds are not dependent on vehicle headlights as the primary light source. These studs use LEDs as the light emitter. The LEDs are powered by internal batteries which are charged during daylight by solar cells. When darkness approaches the LEDs switch on automatically. These studs are more expensive than passive types and are mainly used in areas of poor visibility and increased accident risk.

Non-reflecting studs are used mostly on pedestrian crossings as a tactile demarcation for people crossing the road. They are nominally 100mm square, available in stainless steel and aluminium and are installed into small drilled holes using hot poured bitumen.

We remove inset roadstud by breaking them out using powered roadbreakers. We then backfill with either dense macadam or coated chippings with hot bitumen poured in. We seal macadam backfills with a band of hot poured bitumen (except on roads which are to be surfaced dressed as bleed-through may occur).